Spiral Wound Gaskets Manufacturers

Spiral Wound gaskets are semi metallic products designed for high pressure and temperature application. This type of gaskets can be used in all pressure from vacuum to the standard 2500 psi flange rating. A variety of forms of the gaskets is available and this can be manufactured in a variety of materials or sizes to suit the requirements.

- Spiral wound gaskets are suitable for a wide pressure and temperature ranges.

- Spiral wound gaskets can be used for pressures up to 25 MPa and temperatures from -200°C to +550°C / 1100°C.

- Thanks to its design it can be easily installed without causing and damage.

- The outside guide ring is used to centre the spiral sealing part against the flange and prevents the gasket from blowing out, by combination of various materials and metals, the gaskets can be used in a wide range of operation conditions according to customer specification.

- Thanks to the non-adhesive properties of the spiral wound gasket, it can be easily removed during disassemble.

- The spiral wound gasket does not damage flange surfaces.

- The spiral wound gasket has a very good compressibility and recovery.

Dimensional Standards:

BS 3381– Spiral Wound Gaskets to suit BS 1560 Flanges

Non Metallic Gaskets

These are made from materials that compress easily, such as elastomers like nitrile, (NBR,) EPDM and silicone, as well as graphite, PTFE and fibrous materials. Their corrosion resistance is good but they are limited in the temperatures they can handle. Nitrile gaskets for example only work from -60 to 250°F (-51 to 121°C) and EPDM is only slightly better with a range of -70°F to 350°F (-57°C to 177°C). Silicone gaskets will however go up to 500°F (260°C) and PTFE is effective from cryogenic temperatures up to 450°F (232°C).

Full face gasket types are suitable for use with flat-face (FF) flanges and flat-ring gasket types are suitable for use with raised face (RF) flanges. Soft gaskets are also limited in their ability to handle high pressures. The best applications are those involving sealing variable gaps as might be found around the doors of an electrical enclosure.

Various non-metallic flat gaskets, made from Asbestos, non-asbestos, Graphite, reinforced graphite, PTFE, improved PTFE, mica, and various rubber sheets etc. They are used in a large number by various industries and in a variety of applications. Available are standard and nonstandard gasket design. Non-standard means gaskets can be optional shapes and dimensions according to customer design or sample.

These gasket materials are used for low pressure classes 150lb and 300lb. All the materials described in this section can be supplied in sheeting form or as Cut Joints to meet flange standards or customer-specific dimensions. These materials can be obtained in various thicknesses from 0.50mm to 3.00mm for all materials types listed below. The Rubber materials can be supplied up to 6.00mm thick.

Dimensional Standards:

ANSI B 16.21– Non-Metallic flat Gasket for Pipe Flanges.

Semi Metallic Gaskets

Bridging the gap between metallic gaskets and soft gaskets, the semi-metallics combine features of each. Those gaskets are composites of metal and non-metallic materials. The metal is intended to offer strength and resiliency while the non-metallic portion of a gasket provides conformability and sealability Commonly used semi-metallic are spiral wound, metal jacketed, Cam profile and a variety of metal-reinforced graphite gaskets.

Semi metallic gaskets are designed for the widest range of operating conditions of temperature and pressure. Semi-metallic are used on raised face, male-andfemale and tongue-and –groove flanges.

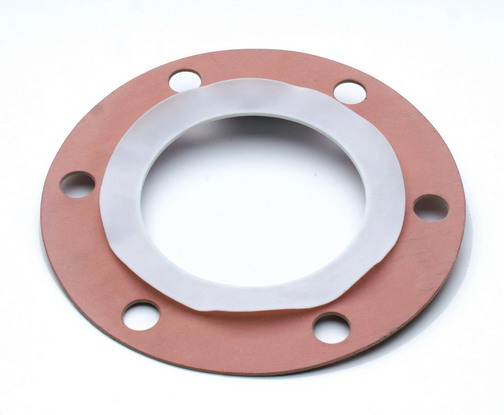

Spiral wound gaskets are used for high temperature and high-pressure applications. The main parts of spiral wound gasket are metallic windings and filler material. The criteria for material selection of windings are: corrosive nature, fluid concentration, operating temperature and material cost. Commonly used material for winding are Stainless steel 304, 316 and 321.Alternate winding materials also can be used depending upon the services. General filler material used are Asbestos and graphite. Graphite filler are recommended for very high temperature application.

For proper positioning, spiral wound gaskets are provided with outer centering ring made up of Carbon Steel. In Vacuum service application they are provided with inner ring. The material of the ring should be compatible with the process fluid.

Spiral wound gasket is recommended with flange face finish of 63-250 AARH.

Double Jacketed gaskets

Metal Jacketed gaskets consist of a soft filer encapsulated in metallic material. The filler material provides the gaskets with compressibility strength and blow out resistance. Jacketed gaskets can be produced in variety of configurations making them ideal for heat exchanger applications. Wide range of Jacket and filler material is available to suit every service condition.

Ring Joint Gaskets

Metallic ring joint gaskets are design for high pressure application. They are available in a variety of forms to suit different flange formats. RTJs come in two type an Oval and an Octagonal cross sections. These basic shapes are used in pressure up to 10000 psi. The octagonal Cross set a higher sealing efficiency the Oval.

PTFE envelope

PTFE enveloped Gasket is a kind of non-metal gasket. normally it is made up by cladding part and packing. the clart,the materiaadding part, which is normally made of teflon function as anti-corrosion pl of packing is non-metal sealing material which has good elasticity and can be with or without metal enhancing layer. this sealing gasket are divided into style v, style u, style l according to the different in frame of inner core. in the field like petroleum, chemical industry, medicine industry,and food industry, we use teflon gasket to make sure the cleanness. and it also used in sealing of strong acid, strong alkali strong oxidizer, chlorine, and other material don’t allow pollution.

PTFE is the most chemiclly inert of the whole wide range of the plastic family being resistant to all known chemicals. It is also suitable for use over very wide tempreature range of the order of -80 degree C to +250 degree C. It also has excellent physical properties, low coefficient of friction, is non -contammating and non-corrosive.

Camprofile Gaskets

- The gasket consists of a metallic core with a grooved profile and sealing layers.

- The gasket can be used for pressures up to 25 MPa and temperatures up to 1000 °C

- The gasket is applicable in a number of applications for all flange types (DIN, ASTM, EN, CSN), it has a sturdy design ensuring uniform pressure distribution on the groove profile

- High reliability during temperature and pressure fluctuation

- The metallic core can be re-used

Corrugated Gaskets

Corrugate gaskets are universally usable sealing elements. Due to the different possibilities of manufacture in the form of Rings of Oval, Long Ovals or frames which can be with or without Ribs, Holes and Fixing Loops. The Gaskets can be completely or Partly covered.

Other Gaskets

- S.S. Washers

- Aluminium gaskets, washers and O rings

- Boiler handhold gasket Oval and square

- Cork sheet gaskets

- Mill board gaskets

- Heat exchanger gaskets

- Plastic / PVC shims

- Asbestos Jointing cut gaskets

- Copper asbestos impregnated washers / gaskets

- Pipe flange gaskets